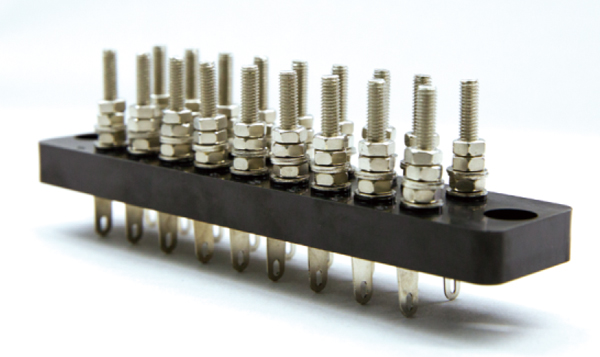

The appearance of side terminal looks simple, but it is also necessary for side terminal to go through strict commodity verification test and periodic production type test. The content, method and determination specification of mechanical function and electrical function of side terminal. First, the purpose of mechanical function test torque test torque test is to test whether the screw has satisfied mechanical strength, so as to ensure no slipping in the process of crimping The appearance of the screw is qualified if the screw does not crack or deform after the test, and the screw head groove does not have the appearance of damage affecting the continuous use. The purpose of crimping experiment is to test the terminal wire without excessive damage to the wire. Connect wires of regular type and extra cross-sectional area with terminals, hang a certain weight, rotate at a speed. After testing, if the wires slide out of the terminal and do not crack near the clamping piece, the terminal crimping is qualified. If there is wire cracking or dropping out of the terminal clamping structure, it is unqualified.

Side terminal electrical function test touch resistance test touch resistance test is to test the static touch function of the terminal, that is, the touch resistance should not be greater than a certain value. Frequency withstand voltage test is to test whether the terminal shell can withstand regular transient or short-term power frequency overvoltage. No flashover or breakdown is allowed during the test. Impulse withstand voltage test is to test whether the terminal shell can accept the regular transient overvoltage. There should be no damaging discharge during the experiment. Voltage drop experiment voltage drop experiment is to test the dynamic touch function of terminals. The voltage drop shall not be greater than a certain value. Temperature rise experiment temperature rise experiment is a test terminal in normal use, its temperature rise can not exceed the regular value, usually the standard regular terminal after the current, its temperature rise can not exceed the ambient temperature. High and low temperature electrical function experiment the electrical function experiment is to test the reliability of the non threaded terminal in normal use. The voltage drop of one cycle at the terminal shall not be greater than a certain value. The side terminal uses the existing track type side terminal connection skills, and is equipped with a circuit composed of electronic components to complete the transmission coupling of the photoelectric process. The center of automatic control is that it is necessary for the control unit to be reliably separated from each sensor and actuator. The terminal can perfectly complete this function, and ensure that the field signal matches the low voltage required by the electronic control equipment. It can also be used as the interface element between the peripheral equipment for process control and the operation control, signal and regulator equipment, and is suitable for different voltage and power Scale.

National Hotline:

024-85632500

E-mail: sy_txt@163.com

Add: A, No. 73, South Central Street, Shenyang Economic and Technological Development Zone