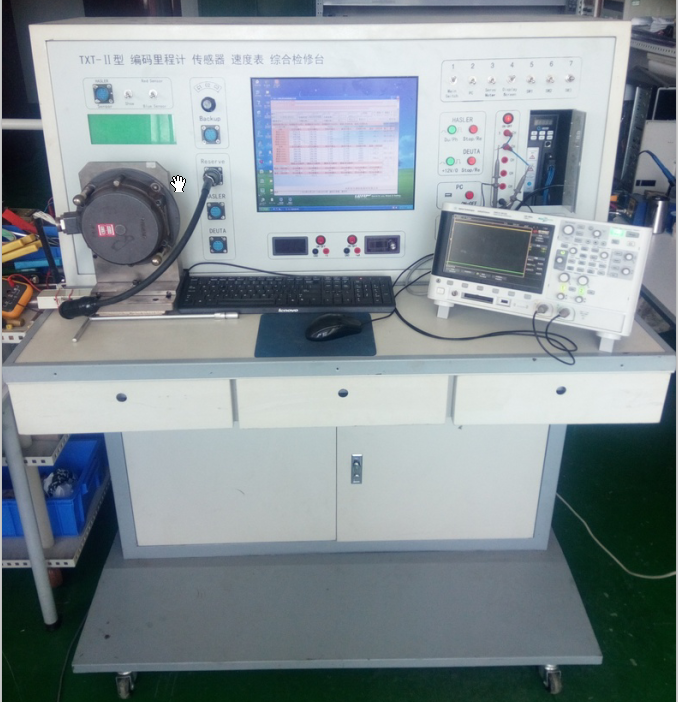

TXT-Ⅱ Coded Odometer/Sensor/Speedometer/Comprehensive Maintenance Platform Function Introduction

The model txt - Ⅱ rotating speed test-bed is developed after accumulated induction and repeated verification in the long-term maintenance practice. It can provide accurate measurement parameters for the maintenance of the speed measuring equipment of rail transit for the reference of maintenance personnel. At present, the integrated maintenance platform can measure the parameters of odometer (photoelectric type), tachometer (photoelectric type and hall type) and double pointer speedometer. The comprehensive maintenance table developed by our company has a strong upgrade space, and we can prepare perfect test means and solutions according to the needs

1、Main Functions:

1. There are two test modes, automatic and manual, which can support five channel electrical parameter measurement

2. Electrical parameters and mechanical fault alarm prompt

3. Printing of maintenance report

4. Maintenance information input function is provided to facilitate users to back up and search measurement data

2、Working Parameters:

1. Speed Measurement Range: 0~2500rpm

2. Number Of Channels: Up to 5 channels of measurement

3. Output Waveform: Square Wave

4. Output Amplitude: High level≥9V, Low level≤2V

5. Pulse Duty Cycle: 50% ±10%

6. Waveform Shifting: ±36°

7. Pulse Phase Difference: 90°±45%(double and four) rotate clockwise facing the output shaft,

7. Pulse Phase Difference: CH1 leading CH2,CH2 leading CH3,CH3 leading CH4.

7. Pulse Phase Difference: 120%±60%(3) Rotate clockwise facing the output shaft,

7. Pulse Phase Difference: CH1 leading CH2,CH2 leading CH3。

8. Working Power Supply: DC12~30V

9. Power Consumption Current: ≤40mA(each channel, no load)

10. Load Current: ≤20mA(per channel)

11. Insulation resistance: Under normal circumstances≥500MΩ, Extreme heat and humidity≥20MΩ(channel to shell and between channels)

3、Equipment advantages:

The txt-ii comprehensive maintenance platform can test the performance parameters of the odometer, speed measuring motor (photoelectric type, hall type) and speedometer according to the requirements. The equipment adopts high-performance servo motor, which can accurately generate a corresponding number of rotation pulses, accurate speed, accurately simulate and record the train parking position according to the test requirements. The equipment truly simulates the train's moving process from low speed to high speed, verifies whether the odometer, speed measuring motor and speedometer can accurately reflect the train's moving speed by suddenly accelerating and decelerating, and judges whether the maintenance meets the qualification standard by combining the performance parameters of odometer, speed measuring motor and speedometer at different speeds.

The txt-ii comprehensive maintenance platform is divided into automatic and manual measurement modes, which are convenient for maintenance personnel to choose flexibly, equipped with friendly computer software interface, providing functions such as printing, storing measurement results, database sharing and data extraction, and convenient for backup and search. At the same time of detecting the electrical performance of odometer, tachometer motor and speedometer, through the measurement of relevant parameters, it can accurately determine whether there is oil dust in the code disk, whether there is disconnection or poor contact in the cable, whether there is deformation in the shell, whether there is eccentricity in the shaft, which can reliably solve the mechanical noise, comprehensively and effectively solve the mileage Electrical and mechanical faults of tachometer, tachometer motor and speedometer.

National Hotline:

024-85632500

E-mail: sy_txt@163.com

Add: A, No. 73, South Central Street, Shenyang Economic and Technological Development Zone